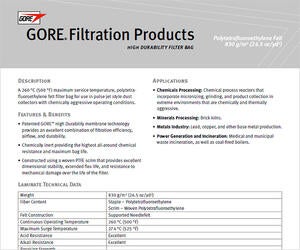

Data Sheet: PTFE Felt Filter Bag 830 g/m2 (24.5 oz/yd2)

Data Sheets, Inglés

A 260 °C (500 °F) maximum service temperature, polytetrafluoroethylene felt filter bag for use in pulse jet style dust collectors with chemically aggressive operating conditions.

Features and Benefits

- Patented GORE™ High Durability membrane technology provides an excellent combination of filtration efficiency, airflow, and durability.

- Chemically inert providing the highest all-around chemical resistance and maximum bag life.

- Constructed using a woven PTFE scrim that provides excellent dimensional stability, extended flex life, and resistance to mechanical damage over the life of the filter.

Applications

- Chemicals processing: Chemical process reactors that incorporate micronizing, grinding, and product collection in extreme environments that are chemically and thermally aggressive.

- Minerals processing: Brick kilns.

- Metals processing: Lead, copper, and other base metal production.

- Power generation and Incineration: Medical and municipal waste incineration, as well as coal-fired boilers.

Technical Specifications

|

Weight |

830 g/m2 (24.5 oz/yd2) |

|

Fiber content |

Staple – Polytetrafluoroethylene |

|

Felt construction |

Supported Needlefelt |

|

Continuous operating temperature |

260°C (500°F) |

|

Maximum surge temperature |

274°C (525°F) |

|

Acid resistance |

Excellent |

|

Alkali resistance |

Excellent |

| Breaking Strength

• Warp |

890 N/5 cm (200 lb/2 in) wide sample 824 N/5 cm (185 lb/2 in) wide sample |

|

Mullen Burst |

4136 kPa (600 psi) |

|

Thickness |

1.07 mm (0.042 in) |

|

Thermal Stability |

< 2% shrinkage at 260°C (500°F) after 2 hours (unrestrained) |

|

Durability |

Very good |

FOR INDUSTRIAL USE ONLY

Not for use in food, drug, cosmetic or medical device manufacturing, processing, or packaging operations.