GORE® MEMS Protective Vents

Gore, the world leader in understanding expanded polytetrafluoroethylene (ePTFE) and its capabilities, offers pioneering venting solutions to protect MEMS microphones. GORE® MEMS Protective Vents provide environmental protection and manufacturing efficiency while enabling in-process acoustic testing in the high-volume assembly of printed circuit boards.

Contacte con nosotros

United States

+1 866 348 4673

Australia

+61 2 9473 6800

Benelux

+49 89 4612 2211

China

+86 21 5172 8299

France

+33 1 5695 6565

Germany

+49 89 4612 2211

India

+91 22 6768 7000

Italy

+39 045 6209 240

Japan

+81 3 6746 2572

Korea

+82 2 393 3411

Mexico

+52 81 8288 1281

Scandinavia

+46 31 706 7800

Singapore

+65 6733 2882

South America

+55 11 5502 7800

Spain

+34 93 480 6900

Taiwan

+886 2 2173 7799

United Kingdom

+44 1506 460123

Overview

There are several technical issues that can jeopardize the integrity of MEMS microphones during the high-volume assembly of printed circuit boards for smartphones, smartwatches, earbuds and other consumer devices.

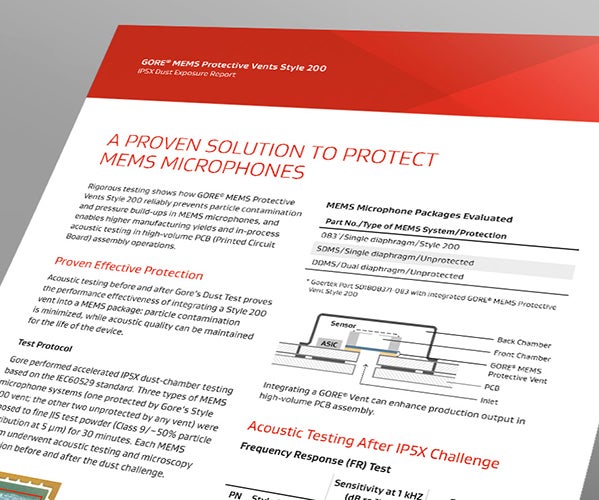

Working directly with OEMs, microphone manufacturers and contract manufacturers, Gore has developed unique venting products proven to provide microphone protection by preventing particle contamination and pressure build-ups, and allowing in-process acoustic testing. Reliable particle protection also helps to prevent mic failure during the manufacturing process.

Additionally, as devices get smaller, installing traditional vents in the ever-shrinking acoustic channels of mobile electronics becomes more challenging.

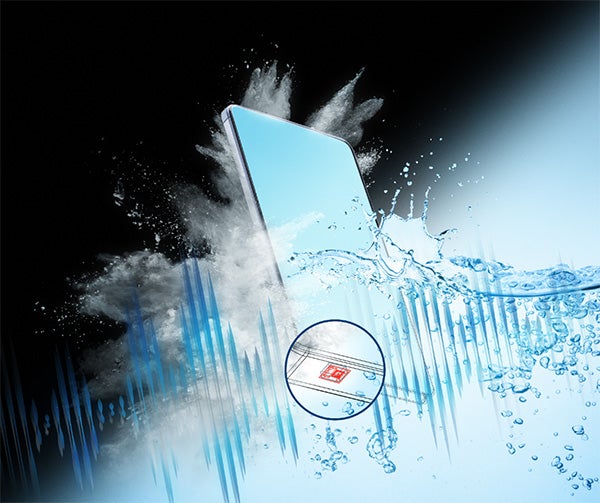

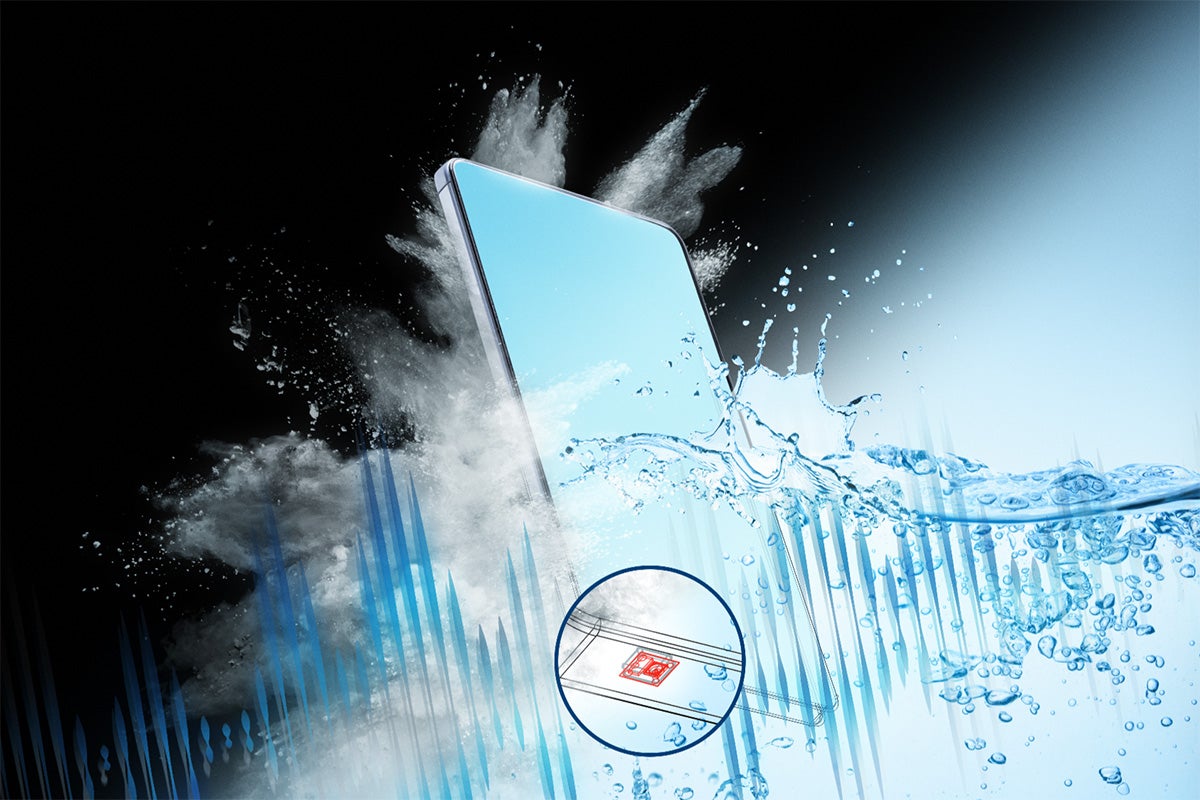

Our latest venting solution, the GORE® MEMS Protective Vents – Style 300, is rated IP68, offering component-level water and dust ingress protection, eliminating the need for installing separate water protected acoustic vents on the device entirely.

With our advanced materials technology, device OEMs can improve acoustic consistency, unlock operational efficiencies, and cut costs.

Applications

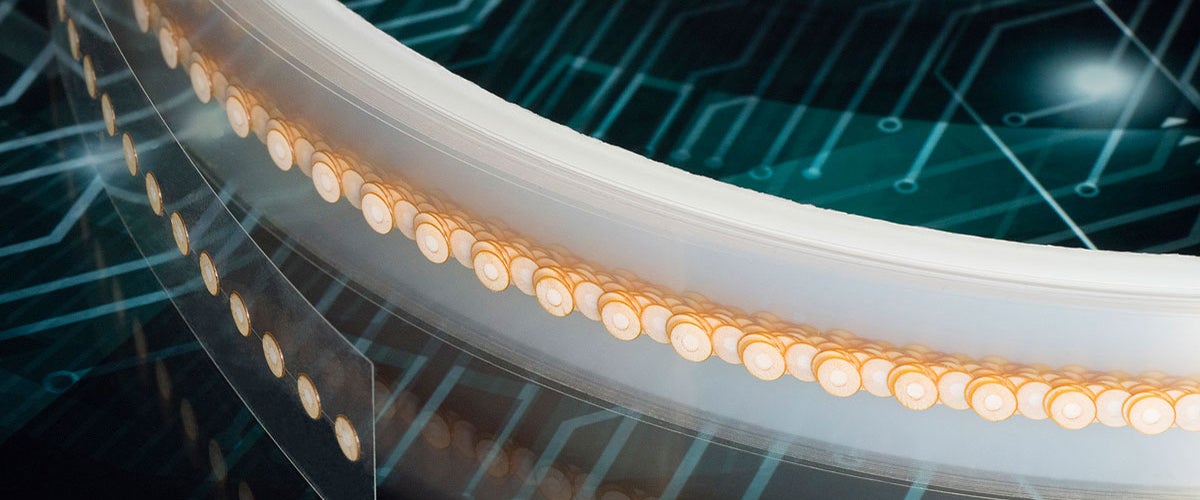

GORE® MEMS Protective Vents are available in three formats designed to meet the specific needs of both circuit board assembly and microphone manufacturers. They are ready to handle the extreme stresses of high-volume, high-speed installation, as well as multiple reflow cycles of up to 280 ºC (390ºF) for 40 seconds.

Wherever MEMS microphones are used, GORE® MEMS Protective Vents can protect the microphone from particle contamination (Style 100, 200 & 300) or even water immersion (Style 300 only). The expanded PTFE membrane also prevents pressure build-ups that may cause damage to the microphone.

GORE® MEMS Protective Vents have been stringently tested and proven to prevent particle contamination and pressure build-ups. Our vents also allow in-process acoustic testing and integrate seamlessly into automated dispensing and placement processes. The GORE® MEMS Protective Vents - Style 300 provides IP68 water protection for microphones.

PARTICLE PROTECTION

GORE® MEMS Protective Vents are unique in that they provide reliable particle protection and reduce contaminants, helping to secure the SMT process, improve production yields and reliably control manufacturing costs.

PRESSURE EQUALIZATION

Gore's experience in providing vents with excellent airflow has been applied to the GORE® MEMS Protective Vents. The breathable ePTFE membrane of the vent allows gasses to pass through the microphone port to mitigate pressure build-ups that may cause damage to the microphone.

IMMERSION PROTECTION*

An integrated design installed at the MEMS microphone package enables component-level water and dust resistance with an IP68 rating.

*GORE® MEMS Protective Vents – Style 300 only

IN-PROCESS TESTING

Gore has developed a technology that both enables in-process testing of acoustic performance and improves process efficiency by allowing manufacturers to monitor sound quality and permeability within the device and alleviating the need to assign resources further down the production line for re-testing.

SEAMLESS INTEGRATION

Gore has manufactured over 1.5 billion GORE® MEMS Protective Vents designed to handle the intense rigor of high-volume, high-speed installation, as well as multiple reflow cycles of up to 280°C for 40 seconds.

Product Data

Gore offers three formats to choose from:

|

Style |

Form |

Protection |

|---|---|---|

| 100 | Reel | Dust |

| 200 | Wafer | Dust |

| New 300 | Wafer | Water & dust |

Style 100 - for circuit board assembly

- Can be installed over the top of a top-port microphone or on the circuit board opposite a bottom-port microphone

- Available in reel packaging

- Enables seamless installation with high-speed SMT pick and place machines

Product Performance Characteristics *

|

Membrane Type |

ePTFE |

|

Membrane Characteristic |

Hydrophobic |

|

Membrane Color |

White |

|

Min. Airflow |

10 L/hr @70 mbar |

|

Adhesive Type |

Silicone based |

|

Adhesive Temp. Resistance |

Max. 260°C for 3 mins |

*Can be customized based on the specific needs of the application

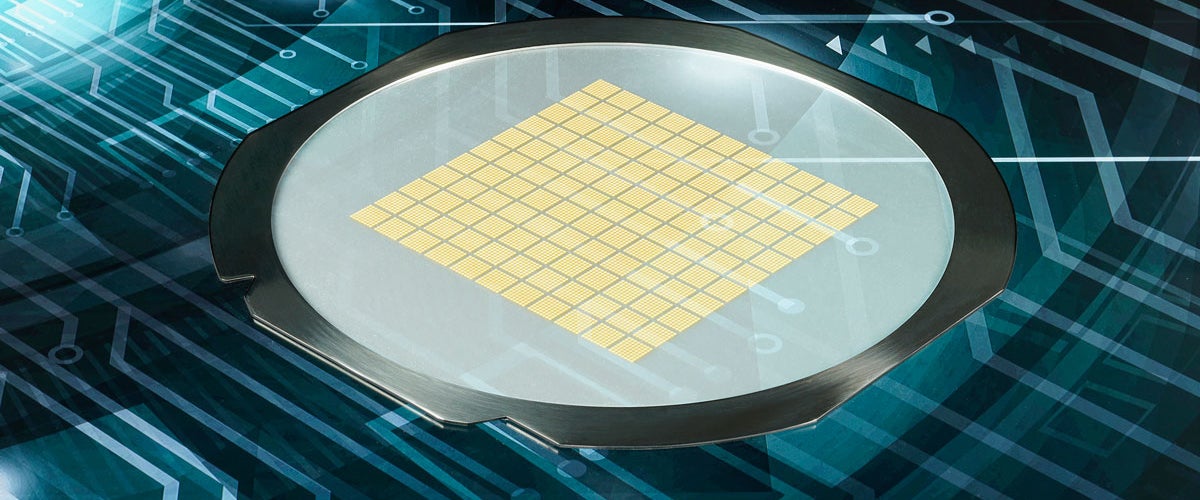

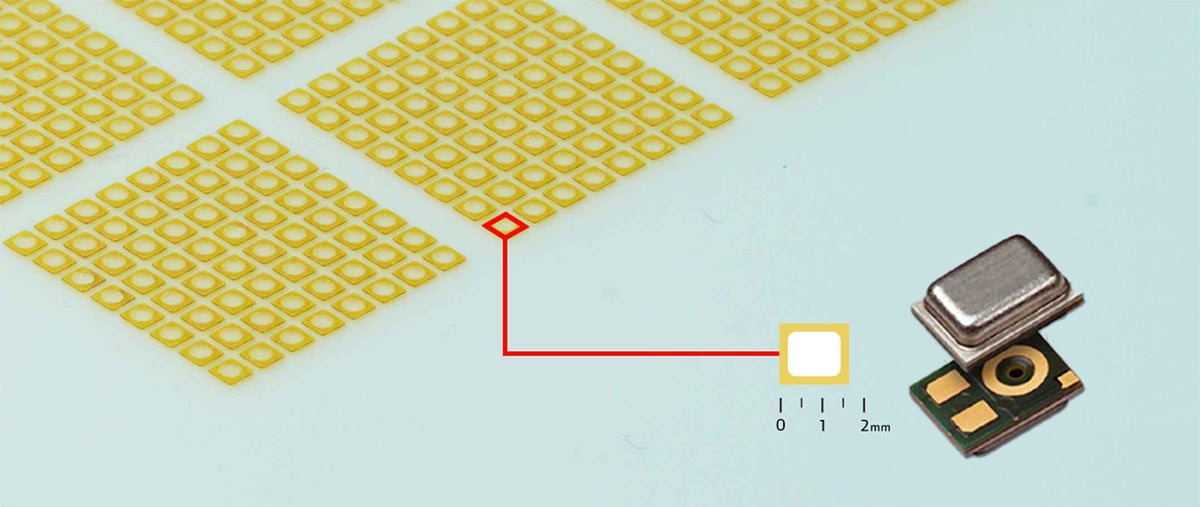

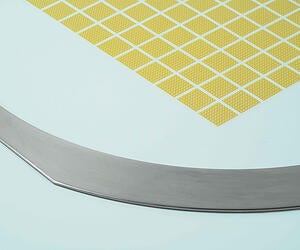

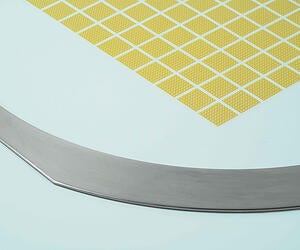

Style 200 - for microphone manufacturers

- Can be installed inside the MEMS microphone during the microphone packaging process

- Parts digitally mapped in a wafer format

- Compatible with high-speed die-attach equipment

Product Performance Characteristics *

|

Membrane Type |

ePTFE |

|

Membrane Characteristic |

Oleophobic |

|

Membrane Color |

White |

|

Min. Airflow |

6 L/hr @ 12 mbar |

|

Adhesive Temp. Resistance |

Max. 280°C for 40 sec for 5 cycles |

|

Particle Retention |

>99% @ 5 µm |

*Can be customized based on the specific needs of the application

NEW STYLE 300 - FOR MICROPHONE MANUFACTURERS (WATER & DUST PROTECTION)

- Can be installed inside the MEMS microphone during the microphone packaging process

- Parts digitally mapped in a wafer format

- Provides component-level IP68 water protection

- Eliminates the need for a separate acoustic vent installed on the housing

- Reduces complexity and saves space in the acoustic channel of water-protected devices, such as IP68 water resistant phones

Product Performance Characteristics

|

Membrane Type |

ePTFE |

|

Membrane Characteristic |

Oleophobic |

|

Membrane Color |

White |

|

Min. Airflow |

11.56 L/hr @ 70 mbar |

|

Adhesive Temp. Resistance |

Max. 280 °C for 40 sec |

|

Particle Retention |

> 90% @ 0.3 µm |

|

Waterproof Capability |

2 meter @ 30 minutes |

Installation and Use

GORE® MEMS Protective Vents are available in three formats designed to meet the specific needs of both circuit board assembly and microphone manufacturers – allowing for installation over the microphone port right before the reflow process, or directly inside the MEMS microphone during the microphone packaging process to provide particle protection without any special handling. Please find our product installation manuals and videos below:

Data Sheet & Installation Guide: GORE® MEMS Protective Vents – Style 100

Data Sheets, Installation Guides, 760.56 KB

Data Sheet & Installation Guide: GORE® MEMS Protective Vents – Style 200

Data Sheets, Installation Guides, 2.17 MB

Why Choose GORE® Portable Electronic Vents for Your Electronic Devices?

Leading OEMs have purchased over 10 billion of GORE® Portable Electronic Vents because they know our products and services can help accelerate their development of innovative and differentiated devices in fast-paced, highly competitive markets.

Product & Application Leadership

Grounded in a deep understanding of materials science and acoustics, Gore can provide the optimum venting solution. We balance trade-offs between diverse problems such as adverse operating environments, immersion events and acoustic performance.

Reliable Performance

To ensure products are “fit for use”, every Gore product must adhere to the highest standards of quality, performance and reliability. Through a comprehensive understanding of end-use applications and requirements, our products do what they say they will do.

Fast Development

The mobile electronics industry develops and releases new products quickly. Our fast response to customer requests during the development process sets us apart. Gore supports this need for quickness with designs and prototypes to ensure engineering teams can meet their project timelines and their application requirements.

Supply Security

Leading OEMS specify Gore because we have consistently proven our ability to quickly ramp up to supply vents for projects of over 10 million devices per year and to continue to supply high quality products on-time without disruption.

Materials Science

Gore is a global materials science company dedicated to transforming industries and improving lives. Gore develops materials with microporous structures that provide desirable attributes and performance characteristics to engineer vents and other products used in a variety of markets and industries.

Global Support

Our global teams of sales associates, application engineers, manufacturing engineers, and research personnel enable us to provide agile and robust support to customers around the world.

Resource Library

Get all the media and documentation available for GORE® MEMS Protective Vents:

Data Sheet & Installation Guide: GORE® MEMS Protective Vents – Style 100

Data Sheets, Installation Guides, 760.56 KB

Data Sheet & Installation Guide: GORE® MEMS Protective Vents – Style 200

Data Sheets, Installation Guides, 2.17 MB

Noticias recientes

FOR INDUSTRIAL USE ONLY

Not for use in food, drug, cosmetic or medical device manufacturing, processing, or packaging operations.