GORE® Pressure Vents

Engineered by the world leader in environmental protective vents for consumer devices, GORE® Pressure Vents provide superb reliability through exceptional balance of airflow and water protection.

Contacte con nosotros

United States

+1 866 348 4673

Australia

+61 2 9473 6800

Benelux

+49 89 4612 2211

China

+86 21 5172 8299

France

+33 1 5695 6565

Germany

+49 89 4612 2211

India

+91 22 6768 7000

Italy

+39 045 6209 240

Japan

+81 3 6746 2572

Korea

+82 2 393 3411

Mexico

+52 81 8288 1281

Scandinavia

+46 31 706 7800

Singapore

+65 6733 2882

South America

+55 11 5502 7800

Spain

+34 93 480 6900

Taiwan

+886 2 2173 7799

United Kingdom

+44 1506 460123

Overview

When a device experiences temperature or altitude changes, a pressure differential between the external environment and the interior of the device can occur. This pressure differential can weaken the gaskets and seals within the device and eventually leads to lower resistance to liquid penetration.

The latest smart phones and many other consumer electronic devices are now made with a flexible, touch-sensitive screen that deflects inward. Consumer handling of these electronic devices can cause rapid pressure changes and pressure differentials between the inside and outside of the device, leading to transducer bias and compromised acoustic performance. GORE® Pressure Vents are engineered to provide optimum airflow within the available design envelope without compromising the required level of ingress protection.

Applications

GORE® Pressure Vents help to equalize pressure fast, minimizing the pressure differentials that can weaken the gaskets and seals within a device, create transducer bias and compromise acoustic performance.

Our range of pressure venting solutions are designed to significantly increase airflow and protect portable electronic devices against rapid pressure changes without compromising on liquid and particulate protection.

Product Comparison

GORE® Pressure Vents

Gore application engineers have a number of pressure vent material sets available to design the optimum vent for your applications.

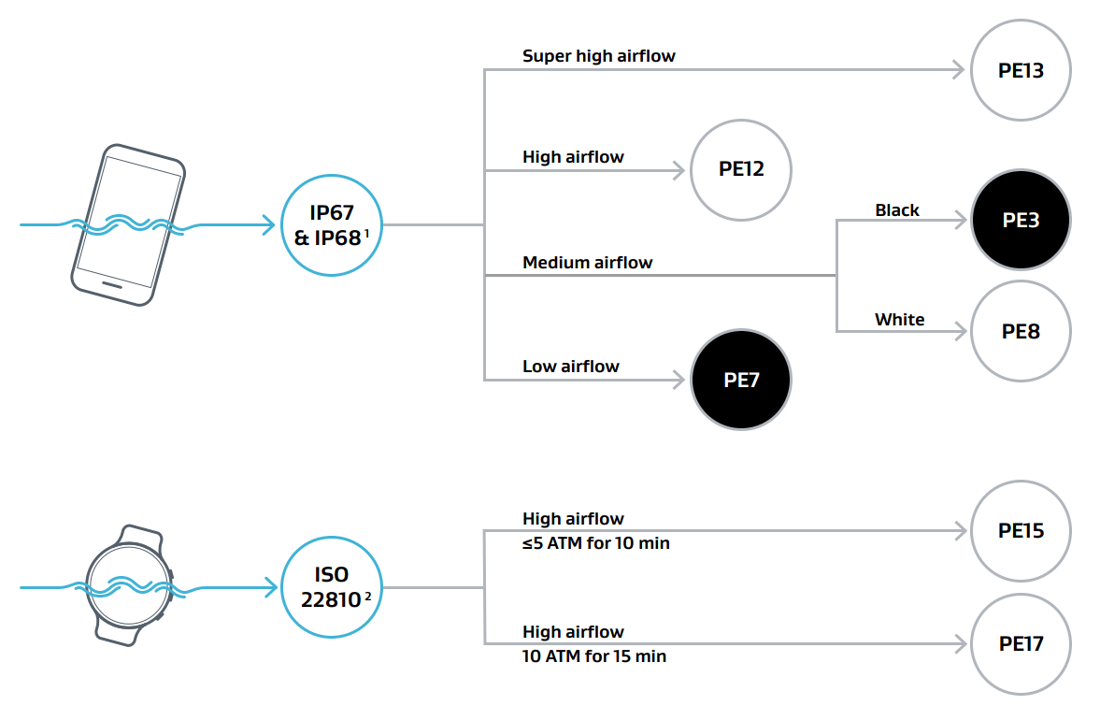

Which product is right for you?

1 With appropriate design conditions (please consult Gore associates).

PE12 and PE13 can meet IP68 (1.5 m water for 30 minutes).

Normally, PE3 and PE8 can meet IP67. For certain designs, IP68 (1.5 m water for 30 minutes) can be met.

PE7 can meet IP68 (2 m water for 1 hour).

2 In compliance with ISO22810:2010(E) test method 4.3.2 Water resistance to overpressure.

GORE® Pressure Vents Data Sheet

Data Sheets, 1.16 MB

Application | Smartphones, Two-Way radios, Scanners | Wearables | |||||

Characteristics/ Performance | PE13 | PE12 | PE8 | PE3 | PE7 | PE15 | PE17 |

IP rating | IP67, IP682 | IP67, IP682 | IP673 | IP67, IP684 | IP67, IP68 | ||

ISO rating (ISO 22810)10 | N/A | N/A | N/A | N/A | 50 m water | 100 m water | |

Typical airflow | 19,000 | 10,000 | 3,300 | 3,300 | 290 | 380 | 290 |

Reference thickness5 | 0.24 mm | 0.24 mm | 0.27 mm | 0.27 mm | 0.34 mm | 0.29 mm | 0.42 mm |

Adhesive type6 | Silicone/ Acrylic | Silicone/ Acrylic | Acrylic | Silicone | Acrylic | ||

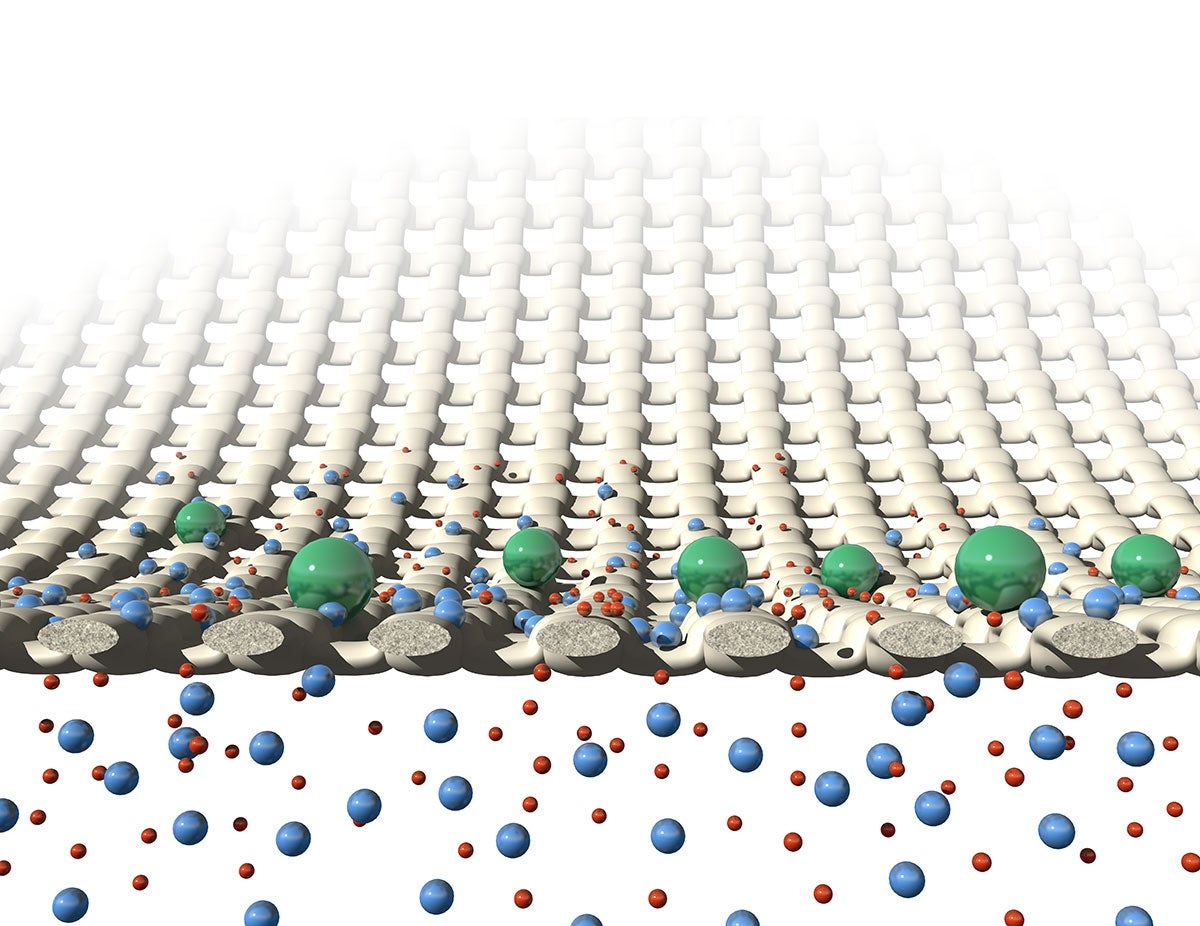

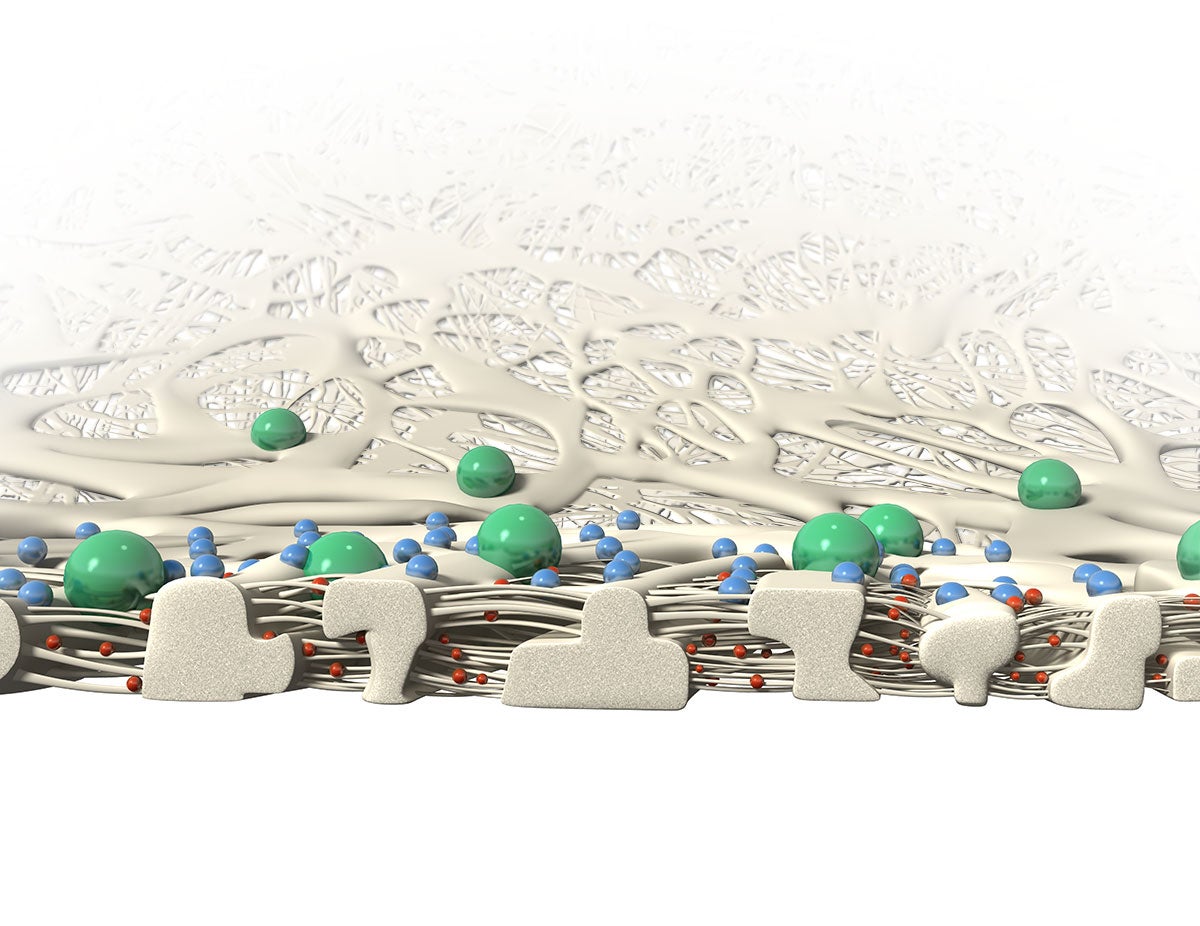

Membrane type | ePTFE | ||||||

Membrane characteristic | Oleophobic | ||||||

Membrane color | White | Black | White | ||||

Support material | PET | PET Non-woven | None | PET | |||

Part orientation | Internal mount with ePTFE facing environment | Mount on the interior or exterior of the housing | | ||||

Adhesive temperature range | -40 °C to 100 °C | ||||||

RoHS7 | Meet threshold requirements | ||||||

1 IP ratings depend on housing design and part size.

2 Extended immersion testing: 1.5 m water immersion for 30 minutes.

3 PE8 and PE3 can meet IP68 (1.5 m water @ 30 minutes) with certain custom design conditions. Please contact Gore associates for details.

4 Extended immersion testing: 2 m water immersion for 1 hour. PE7 can also meet IP65 and IP66 under external mount condition only.

5 Actual thickness may vary due to the compressibility of nonwoven, ePTFE and adhesive layers.

6 A wide range of options available as a custom product.

7 To the best of our knowledge, the parts listed above do not have any restricted substances above the maximum concentration values listed in RoHS Directive 2011/65/EU.

8 Extended immersion testing: 50 m water immersion for 10 minutes with back pressure on captive ring.

9 Extended immersion rating: 100 m water immersion for 15 minutes with back pressure on captive ring.

10 In compliance with ISO22810:2010(E) test method 4.3.2 Water resistance to overpressure.

11 PE7 can also be mounted on the interior of the housing, and have therefore the waterproof adhesive facing the interior environment.

This information is based on our current level of knowledge and does not constitute a representation or warranty beyond those contained in our standard terms and conditions.

Design Considerations

Predicting the conditions your product will encounter can be difficult, so our application engineers will work with you to ensure the right vent is selected.

Factors that might be considered include:

- What are the required product dimensions (device air volume)?

- How will the product be used?

- What are the air flow requirements of your device?

- What is the target pressure equalization time?

- What are the minimum and maximum temperatures your device may face?

- What surface will the vent be mounted on and what type of adhesive is required?

- How much space is available within your device enclosure? Will there be an open cavity?

Standard Parts

| Dimension (mm) | Part Number | |||||||

|---|---|---|---|---|---|---|---|---|

| Inner Diameter | Outer Diameter | PE13 | PE12 | PE8 | PE3 | PE7 | PE15 | PE17 |

| 1.6 | 4.2 | - | - | - | - | - | - | - |

| 2.0 | 5.0 | PE130205 | PE120205 | PE80205 | PE30205 | - | - | - |

| 3.0 | 6.0 | PE130306 | PE120306 | PE80306 | PE30306 | PE70306 | - | - |

| 5.0 | 9.4 | - | - | - | PE30509 | - | - | - |

| 5.5 | 10.2 | - | - | PE80510 | - | PE70510 | - | - |

| 1.6 | 3.8 | - | - | - | - | - | PE151.63.8 | - |

| 2.0 | 4.2 | - | - | - | - | - | PE152.04.2 | PE172.04.2 |

Available in custom and standard sizes to give manufacturers greater design flexibility — to either reduce the number of pressure vents used in their devices or reduce the size of pressure vents for devices with limited internal space — without reducing effectiveness.

Gore applications engineers are also available to assist in selecting the right solution for your specific application requirements.

Installation and Use

Working directly with OEMs and manufacturers, GORE® Pressure Vents have been developed to easily be applied manually or as part of high-volume manufacturing processes and automated installation procedures. Please see below for our product installation video:

Why Choose GORE® Portable Electronic Vents for Your Electronic Devices?

Leading OEMs have purchased over 10 billion of GORE® Portable Electronic Vents because they know our products and services can help accelerate their development of innovative and differentiated devices in fast-paced, highly competitive markets.

Product & Application Leadership

Grounded in a deep understanding of materials science and acoustics, Gore can provide the optimum venting solution. We balance trade-offs between diverse problems such as adverse operating environments, immersion events and acoustic performance.

Reliable Performance

To ensure products are “fit for use”, every Gore product must adhere to the highest standards of quality, performance and reliability. Through a comprehensive understanding of end-use applications and requirements, our products do what they say they will do.

Fast Development

The mobile electronics industry develops and releases new products quickly. Our fast response to customer requests during the development process sets us apart. Gore supports this need for quickness with designs and prototypes to ensure engineering teams can meet their project timelines and their application requirements.

Supply Security

Leading OEMS specify Gore because we have consistently proven our ability to quickly ramp up to supply vents for projects of over 10 million devices per year and to continue to supply high quality products on-time without disruption.

Materials Science

Gore is a global materials science company dedicated to transforming industries and improving lives. Gore develops materials with microporous structures that provide desirable attributes and performance characteristics to engineer vents and other products used in a variety of markets and industries.

Global Support

Our global teams of sales associates, application engineers, manufacturing engineers, and research personnel enable us to provide agile and robust support to customers around the world.

Case Studies

Read about how the GORE® Portable Electronic Vents team of engineers and scientists are working with customers to ensure delivery of the best possible venting, production and customized solutions:

Mastering Complexity in the Evolution of Smartphones

Case Studies

Reliable Performance for an Adventurous Lifestyle

Case Studies

Resource Library

Get all the media and documentation available for GORE® Portable Electronic Vents:

Installation and Handling Guidelines for Portable Electronic Vents

Installation Guides, 915.05 KB

Extended Water Entry Pressure Test Guideline

Technical Information, 821.41 KB

GORE® Pressure Vents Data Sheet

Data Sheets, 1.16 MB

GORE® Pressure Vents Product Model PE13 Brochure

Brochures, 204.65 KB

Noticias recientes

FOR INDUSTRIAL USE ONLY

Not for use in food, drug, cosmetic or medical device manufacturing, processing, or packaging operations.